Organizations set strategic missions, have a vision for growth, profitability and productivity targets. However, implementation of EHS management system cannot be undermined as safety and health targets override all production targets. Oil & Gas industries are set up globally considering geographic and technical challenges to implement EHS management system effectively. Oil and Gas industries are different from other industries in terms of managing safety as they have a higher degree of risk and associated severity compared to other industries.

The International Association of Oil & Gas Producers (IOGP) explains that Process Safety Management is a “disciplined framework for managing the integrity of operating systems and processes that handle hazardous substances,” and the goal is to prevent unplanned releases of hazardous materials or energy to prevent structural failure or loss of stability that could lead to a major incident. There were 56 process safety events between 2007 and 2017 that led to 128 deaths.

in March 2021, five workers were injured and hundreds evacuated after a massive blaze at West Java oil refinery in Indonesia. The cause of the fire is unknown, the investigation’s still underway. The state oil firm said it was shutting down the refinery and conducting “oil flow control” to prevent any further spread. There has been an increase of similar incidents in the oil and gas industry.

The Oil & Gas industry involves high-risk activities like exploration, oil production and processing of highly flammable & explosive materials. These industries have complicated & expensive technology, machinery and they need highly skilled, trained, experienced manpower and extensive support services management system. The investment is quite high and payback periods long with limited benefits. These industries are strategic and vitally situated at remote locations and not very environment friendly. In case of any untoward incident/ accident, it can lead to catastrophic failures in terms of the number of casualties and unsafe/ unhealthy environment and such.

The Oil and Gas manufacturing business varies from country to country & region to region. The local culture, climate, customs, client services and business processes influence day-to-day functions to achieve production target, safety, and health goals. The local regulation and statutory norms must be stricter and more stringent so that the concept of risk acceptability is more conservative, considering the importance of safety and health of Oil and Gas manufacturing units. As a result, safety and health management becomes a catalyst in enhancing productivity, profitability, growth, and efficiencies to drive business. The safety and health professionals at the local plant level as well as at the corporate level need to be involved at the conceptualization and planning stage of the project as well as during the expansion of an existing unit. To manage safety and health, local leadership must understand the concept and value and consider proven efficient technology and plant machinery. At the same time, it is equally important to ensure the deployment of skilled, experienced manpower and necessary resources for all aspects of safety and health.

Oil & Gas Industry Hazards:

For Oil and Gas industry, hazard elimination is almost impossible by virtue of it being inherently a high-risk industry. Basically, there are two types of safety engineering: Process Safety and Occupational Safety. Process Safety focuses on preventing fire, explosions, and accidental chemical release in process facilities. Occupational Safety & Health focuses on personal safety. Safety at Oil & Gas plants also focusses on specific procedures, guidelines, and permit to work system. PPE (Personal Protective Equipment) is to be considered as the last protection to humans but at the same time, certain jobs need special PPE in addition to standard PPE (for example, welding masks for a welder and not just safety glasses). Specialized trade-specific training for personnel working in dangerous locations like for Oil & Gas Industry are to be conducted periodically.

Process Safety

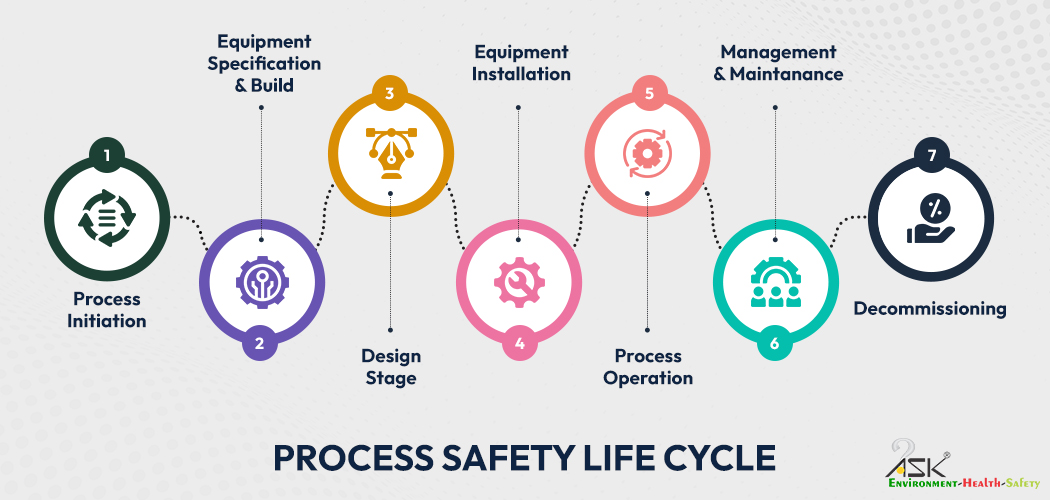

Since inception, Process Safety begins with an idea & continues through various stages of development.

- Process Safety Life Cycle: Process Initiation > Equipment Specification & Build > Design Stage > Equipment Installation > Process Operation > Management & Maintenance > Decommissioning

- Identification of any hazardous situation followed by preventive measures is a pre-requisite for safe operation.

- It involves an in-depth knowledge of the materials in use, process operation, equipment specification & the facilities.

Process Safety Management Includes:

- Inherently Safe Design from concept to commissioning and normal operation/maintenance

- Design user-friendly plants which can withstand human errors and equipment failure without serious effects on safety, environment, productivity, and efficiency

Process Design Analysis

- Hazard Analysis

- Risk Analysis

- Guidelines for estimating Losses

- Project Reviews and Procedures

Safe Design and Operations consideration

- Principle of Inherent Safety

- Approach to Risk Assessment

- Ensure Competence and adequacy of resources

- Work within the defined safe operating system

- Take control of changes that could impact process safety

- Maintain up to date documentation

- Establish line management monitoring of safety system and procedure

- Conduct independent audits of management & technical parameters

- Analysis and investigation of incidents to establish root causes

- Prepare a schedule to review process safety performance on a regular basis

- Regularly update improvement plans

Approach to Process Safety

Here the steps are mentioned for Process Safety

- Identification of Hazards

- Determination of the level of Risk

- Implementation of necessary safeguards which forms the basis of safety

- Attention to process safety risks

- The threat of legal action for noncompliance

- Loss of valuable Assets

- Potential for serious injury or fatality in worst case scenario

- Loss of Production and income

- Unwelcoming media attention

- Damage to company’s Reputation

- Potential for increased Insurance Premium

Commitment to Process Safety

Commitment is the first step in safeguarding that a culture of process safety is embedded within a business, and includes the following elements:

- Leadership/Management commitment;

- Accountability/roles and responsibilities;

- Process safety culture;

- Company standards, codes & regulations; and

- Workforce and stakeholder involvement.

Process Safety has a better approach than the traditional approach to accident prevention. There is a practice of foreseeing hazards before incidents/accidents occur. There is more emphasis on a systematic rather than a trial-and-error approach to identifying hazards and estimating the probability of their occurrence and subsequent consequences. In Oil & Gas Industry, accidents tend to happen infrequently but when they happen, they lead to catastrophic results, rapid over pressure, rapid decomposition of thermally unstable substances or mixtures and runaway exothermic chemical processes, besides others. Several directives are to be implemented to ensure satisfactory protection of personnel working within oil & gas process industries. The main component of an effective EHS management system is to manage Process Safety. Operational safety supports to achieve and maintain a high level of process safety standard and mechanical integrity. A barrier approach, combined with safety management systems and culture programs will be successful, provided, they are applied fully in combination with reliability /integrity services.

Process Safety way forward

For good risk assessment and control, both a scientific exploration of hazard scenarios and managerial commitment are required. Knowledge of chemical engineering principles and safety technologies allows the risks to be minimized effectively and economically. It must become part of management system and a corporate culture. Knowing the critical conditions is a prerequisite for assessing the safety of operations and hence needs a careful consideration. The message to the management, is to invest into chemical reaction engineering and motivate development people to integrate safety into their processes. One can arrive at inherently safer processes by following the methodology mentioned above.

Process safety is a team effort at the end of the day!

Towards the completion Journey of the 15th year in EHS services. Globally more than 1100 worksites have been assisted by our 26000 EHS personnel deployed on site to enhance the safety management system.

Connect with us to know how we at ASK-EHS can help you achieve workplace safety at all times by comprehensive assessment of your projects with our expert safety professionals.